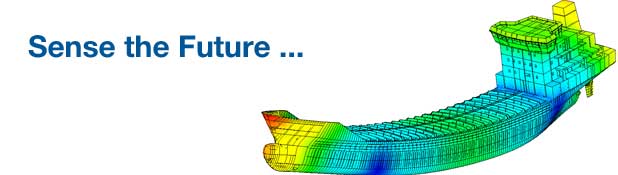

Advanced engineering analysis can be described as the representation of a physical structure with a numerical mesh divided into elements of finite number and solution of differential equations belonging to a specific physical problem on this numerical mesh by using appropriate boundary conditions. This method is on the leading edge for engineering problems so complicated that they can’t be solved by using analytical methods. In a sense this is physical simulation or virtual reality.

Advanced engineering analysis can be described as the representation of a physical structure with a numerical mesh divided into elements of finite number and solution of differential equations belonging to a specific physical problem on this numerical mesh by using appropriate boundary conditions. This method is on the leading edge for engineering problems so complicated that they can’t be solved by using analytical methods. In a sense this is physical simulation or virtual reality.

Delta Marine uses and proposes advanced engineering technology and tools to bring the developed designs to perfection in terms of economy, functionality, respect to environment, safety, performance, aesthetic, ergonomics. Delta Marine which has experienced the use and benefits of the advanced engineering technology in various ship design project of different type and tonnage, has the knowledge and capability to perform ship design projects of more shipyard-friendly, more robust, more ergonomic, more user-friendly, less costly, more environment-friendly and more lean nature.

The effects of the advanced engineering analysis on ship design processes and the benefits to ship-owners can be defined as follows,

Ship’s structure can be optimized both in terms of robustness and weight.

Critical areas or points of the ship can be determined. This allows to pay special attention on these areas during maintenance and thus the operational lifetime of the ship is increased.

The underwater and surface hull form of the ship can be optimized in terms of resistance and propulsion. Fuel consumption and the diffusion of the greenhouse gases is decreased.

Crew’s comfort is guaranteed with noise and vibration analysis.

Equipment functionality analysis is carried out by mechanism simulations and absence of any function is avoided.

The advanced engineering analyses that are carried out by Delta Marine for ship design verification are categorized in two main groups.