|

|

|

|

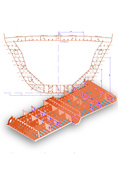

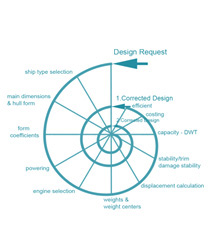

At

the early stages of the design process, Delta Marine determines

the parameters that will form the basis for optimum ship dimensions,

hull form as well as the selection of propulsion system's type

and power and auxiliary systems, according to the customer's requirements

(for example, speed, DWT, number of passengers, number of vehicles

etc.). Concerning the conceptual design stage of the project,

Delta Marine provides the services stated as below At

the early stages of the design process, Delta Marine determines

the parameters that will form the basis for optimum ship dimensions,

hull form as well as the selection of propulsion system's type

and power and auxiliary systems, according to the customer's requirements

(for example, speed, DWT, number of passengers, number of vehicles

etc.). Concerning the conceptual design stage of the project,

Delta Marine provides the services stated as below

Determination of main dimensions according to ship type, speed

and carrying capacity

Determination of main dimensions according to ship type, speed

and carrying capacity

Preliminary form design

Preliminary form design

Speed-power analysis

Speed-power analysis

Calculation of preliminary stability, trimmed and damaged stability

conditions

Calculation of preliminary stability, trimmed and damaged stability

conditions

Calculation of preliminary weight distribution

Calculation of preliminary weight distribution

Calculation of longitudinal strength

Calculation of longitudinal strength

Subdivision calculations

Subdivision calculations

Preparation of preliminary general arrangement

Preparation of preliminary general arrangement

Calculation of capacities

Calculation of capacities

Feasibility studies

Feasibility studies

Preparation of Technical Specification Booklet

Preparation of Technical Specification Booklet

|

|

|

|

|

|

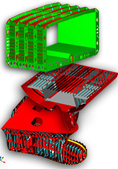

In Delta

Marine, Engineers of Structural Design, who are experts on their

subjects, prepare the optimum structural configuration of ship

dimensions by taking the type of cargo and type of the ship as

reference. Their aim is to use minimum amount of material, to

comply the rules of Classification Society, to develop special

details in critical areas of fatigue and corrosion, to develop

the most suitable structural configuration for workmanship and

vibration. They utilize acknowledged software such as, Classification

Society Software (for example, Poseidon, Safe Hull, Mars etc.)

and Finite Element Analysis Software for all these purposes. The

scope of services of structural design includes,

Design of midship and typical transverse section details

Design of midship and typical transverse section details

Design of ship structure and preparation of general steel construction

drawings

Design of ship structure and preparation of general steel construction

drawings

Preparation of shell expansion and framing system

Preparation of shell expansion and framing system

Preparation of engine room, foundation of main engine and other

machinery equipment

Preparation of engine room, foundation of main engine and other

machinery equipment

Preparation of fore and aft structural details

Preparation of fore and aft structural details

Design of signal masts and crane columns

Design of signal masts and crane columns

Design of hatch covers and ramp

Design of hatch covers and ramp

|

|

| MACHINERY,

OUTFITTING & PIPING |

|

|

|

|

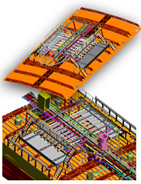

Outfitting and Marine Engineers

who have worked in ships for many years and who have a long onboard

experience, develop projects on arrangements, outfitting and one-line

diagrams of the main and auxiliary engines of the ship. During

this arrangement process, their main aim is to provide safe, ergonomic

and environmental designs. 3D model of piping layout and isometric

drawings are among their experience.

Design and arrangement of engine room

Design and arrangement of engine room

Calculation of the equipment capacities and selection of equipment

Calculation of the equipment capacities and selection of equipment

Design of propeller and rudder shaft systems

Design of propeller and rudder shaft systems

Calculation of boiler capacity, heating coil length, design of

heating systems

Calculation of boiler capacity, heating coil length, design of

heating systems

Design of ladder, railway, windlass-mooring arrangement and other

deck equipment

Design of ladder, railway, windlass-mooring arrangement and other

deck equipment

Design and preparation of piping diagrams

Design and preparation of piping diagrams

Design of exhaust and ventilation ducts

Design of exhaust and ventilation ducts

3 - D pipe modelling and preparation of isometric plans

3 - D pipe modelling and preparation of isometric plans

Preparation of P&A, ODME, Rudder Shaft and Clean Sea manuals

Preparation of P&A, ODME, Rudder Shaft and Clean Sea manuals

Preparation of Fire and Safety plans

Preparation of Fire and Safety plans

Preparation of Damaged Stability control plans

Preparation of Damaged Stability control plans

Preparation of docking and painting plans

Preparation of docking and painting plans

Pressure Drop calculation for P/V circuits

Pressure Drop calculation for P/V circuits

|

|

|

|

|

|

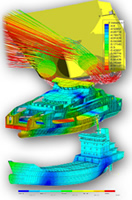

Delta Marine develops own software

to solve Naval Architectural problems as well as company's organizational

needs . A new software is still being developed on ship structure

modelling and production planning. Below, software, which are

developed or being developed by Delta Marine for in-house use,

are determined.

DeltaLoad : Loading

computer software for stability, trim, grain cargo and container

loading and reporting, longitudinal strength calculation, developed

to be used both in office and onboard

B_Surf : Form design, manufacturing and fairing

DeltaHydro : Software for capacity calculation, hydrostatic,

stability cross curves, inclining experiment report, trim &

stability, GM limit curve, longitudinal strength and launching

calculations.

MarineCAD : Software for ship structure modelling and production

planning.

Textus : Application for Document Management, Workflow

Management and Project Management.

|

|

|

At

the early stages of the design process, Delta Marine determines

the parameters that will form the basis for optimum ship dimensions,

hull form as well as the selection of propulsion system's type

and power and auxiliary systems, according to the customer's requirements

(for example, speed, DWT, number of passengers, number of vehicles

etc.). Concerning the conceptual design stage of the project,

Delta Marine provides the services stated as below

At

the early stages of the design process, Delta Marine determines

the parameters that will form the basis for optimum ship dimensions,

hull form as well as the selection of propulsion system's type

and power and auxiliary systems, according to the customer's requirements

(for example, speed, DWT, number of passengers, number of vehicles

etc.). Concerning the conceptual design stage of the project,

Delta Marine provides the services stated as below